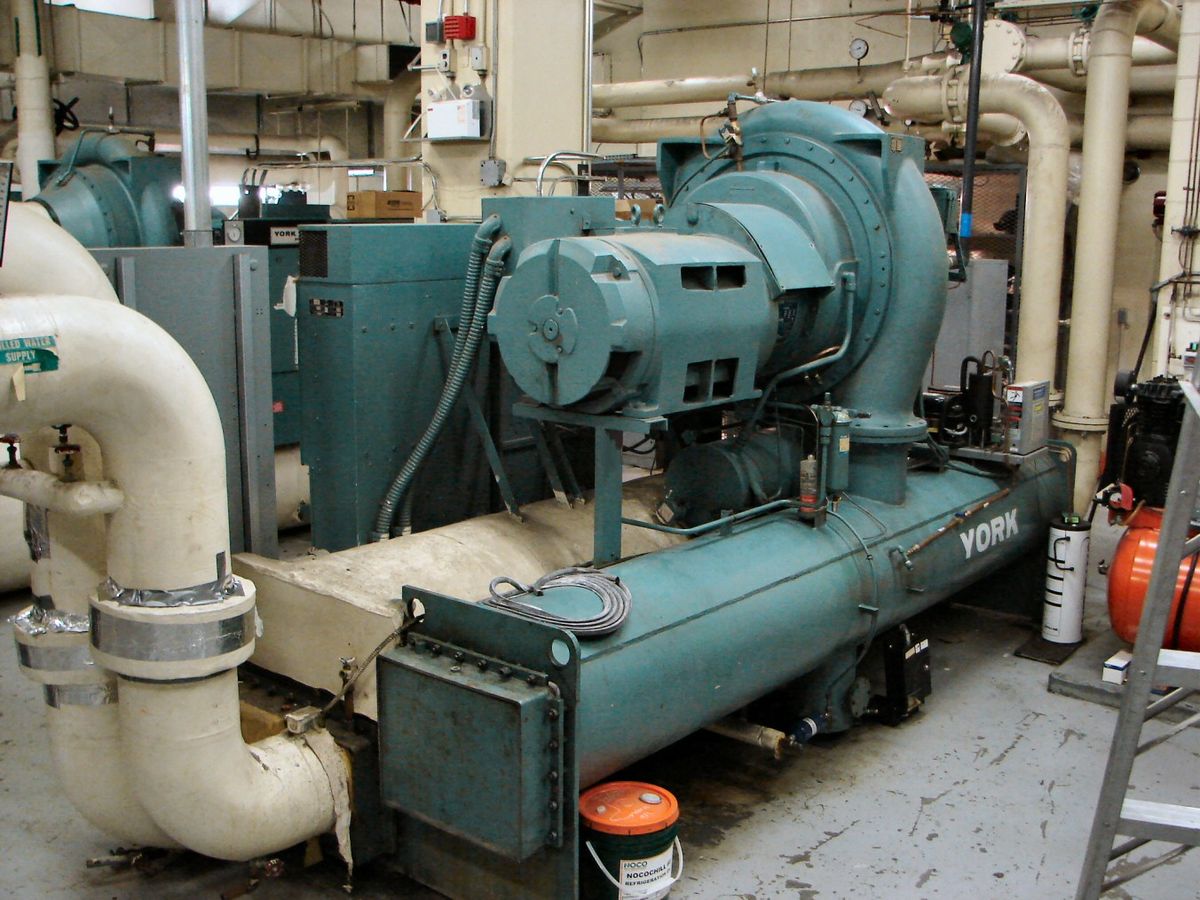

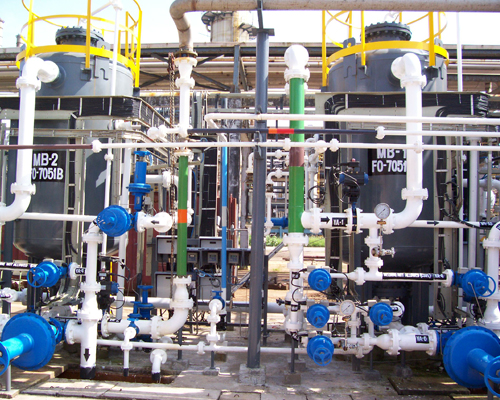

They are used widely across multiple sectors, including municipal water treatment plants, industrial manufacturing units, agricultural irrigation systems, and even residential water purification setups. Chemical dosing can be automated or manual, and the selection of a system depends on factors such as flow rate, water quality, required chemical type, and dosage accuracy.

Why Chemical Dosing Systems Matter Today

Water safety and sustainability are global concerns. Chemical dosing systems play a vital role in solving some of the most pressing issues in water treatment:

-

Health and safety: By precisely regulating disinfection chemicals, these systems reduce pathogens and contaminants.

-

Environmental compliance: Industries must meet discharge standards. Dosing systems ensure treated water is within permissible chemical and biological limits.

-

Operational efficiency: Proper dosing reduces chemical waste, operational costs, and maintenance frequency.

-

Water reuse and recycling: As water scarcity grows, these systems help treat water for reuse in industrial or agricultural settings.

Who benefits:

-

Municipal water boards

-

Industrial facilities (like power plants, food processing, textiles)

-

Hospitals and institutions

-

Commercial complexes

-

Remote and rural water systems

Without effective dosing, water treatment becomes inefficient, potentially harmful, and expensive in the long term.

Recent Trends and Updates

Several new developments have shaped the chemical dosing landscape in the past year:

| Trend | Description |

|---|---|

| Smart dosing systems | Integration with IoT, sensors, and AI for real-time monitoring and predictive dosing. These systems can self-adjust based on incoming water quality data. |

| Green chemical alternatives | Shift toward eco-friendly dosing chemicals to reduce environmental impact, especially in Europe and Southeast Asia. |

| Compact modular systems | Increase in portable and plug-and-play dosing systems for rural and temporary installations. |

| Focus on low-maintenance systems | Manufacturers are prioritizing low-maintenance pumps and anti-clogging technologies, especially for remote setups. |

A 2024 report by the Global Water Intelligence Group showed a 17% increase in demand for automated dosing systems globally, with Asia-Pacific being the fastest-growing market.

Legal and Regulatory Considerations

Chemical dosing for water treatment is strictly regulated across most countries due to the health and environmental implications of incorrect dosing. Some key laws and frameworks include:

-

India: The Central Pollution Control Board (CPCB) and Bureau of Indian Standards (BIS) set the permissible levels of residual chlorine and other chemicals in drinking and industrial water.

-

USA: The Environmental Protection Agency (EPA) governs chemical usage under the Safe Drinking Water Act (SDWA).

-

EU: Under the Urban Wastewater Treatment Directive and REACH regulations, dosing practices must comply with strict guidelines regarding chemical storage, application, and reporting.

-

ISO Standards: ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) often guide suppliers and operators toward safer, certified systems.

Moreover, several countries require trained personnel and safety audits for installing and maintaining dosing systems, especially in critical sectors like hospitals or food processing.

Tools and Resources for Choosing and Managing Dosing Systems

Selecting the best dosing system requires consideration of various operational, chemical, and water parameters. The following tools and resources can help:

Online Calculators

-

Grundfos Dosing Calculator – Helps determine optimal pump size and chemical dose based on flow rate and concentration.

-

Blue-White Flow Verification Tool – Verifies flow rates in chemical feed systems for better accuracy.

Software and Apps

-

WES Water App – Mobile app to monitor and control dosing remotely.

-

SmartDosing® by ProMinent – Offers advanced analytics and remote support for chemical dosing stations.

Educational Resources

-

WHO Water Quality Guidelines – Free downloadable PDFs on water safety and dosing.

-

Water Environment Federation (WEF) – Offers certifications, manuals, and webinars on water treatment technologies.

Supplier Directories and Platforms

-

Alibaba and IndiaMART – For local supplier listings and equipment comparisons.

-

Water Online and Aquatech – For reviews, case studies, and technology updates.

FAQs About Chemical Dosing Systems

1. What is a chemical dosing pump and how does it work?

A chemical dosing pump is a specialized pump designed to inject chemicals into water or other fluids in precise quantities. It operates using a motor-driven or solenoid-based mechanism to push a fixed volume of chemical per stroke or time unit, ensuring accuracy in dosing.

2. How do I choose the right dosing system?

Consider:

-

Water flow rate and pressure

-

Type and concentration of chemical

-

Required dosage accuracy

-

System automation level

-

Maintenance needs and availability of parts

Always consult certified professionals or supplier engineers for sizing and compatibility.

3. Is chemical dosing safe for drinking water?

Yes, when correctly implemented and monitored, chemical dosing is safe and necessary for disinfecting and maintaining water quality. Regulatory bodies like WHO and EPA provide safe limits and guidelines.

4. What maintenance is required for dosing systems?

Routine maintenance includes:

-

Cleaning injection valves and tubing

-

Checking for leaks or wear in pump diaphragms

-

Verifying calibration and flow rates

-

Refilling or replacing chemical storage tanks

-

Ensuring safe chemical handling practices

Final Thoughts

Chemical dosing systems are crucial in maintaining the quality, safety, and reliability of water treatment processes across sectors. With advancements in automation, sustainability, and digital monitoring, these systems are becoming more efficient and accessible than ever before.

When choosing a dosing system or supplier, prioritize those who comply with local and international standards, offer robust after-sales support, and provide scalable solutions. Using available tools and staying informed about regulatory and technological trends can significantly enhance operational safety and water quality outcomes.